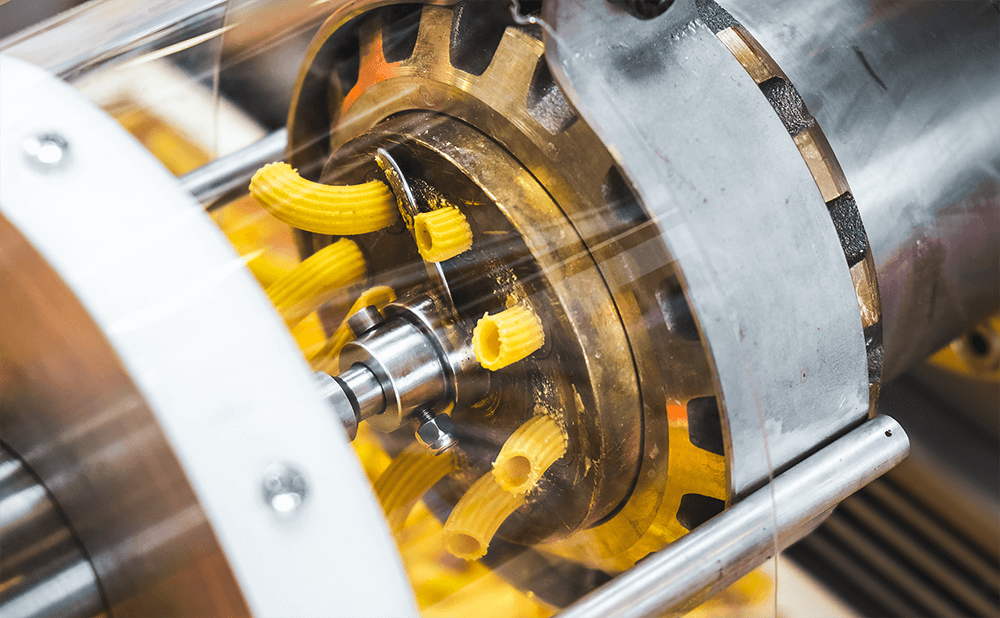

Rotary bearing for extruder

In extruders, the main type of slewing component is a compact slewing bearing or gear with a smaller width compared to standard bearings. This design optimizes space and reduces structural load. A motor drives the gear, generating radial torque through axial movement. The torque is transferred to the slewing bearing and then passed on to the screw via a radial gear. Using a properly selected slewing device or gear significantly enhances equipment performance, reduces wear, extends service life, and ensures smoother and more efficient operation. This is especially critical for continuous, high-load extrusion processes where stability and precision are essential for product quality.