Swivel bearing for displacement machine

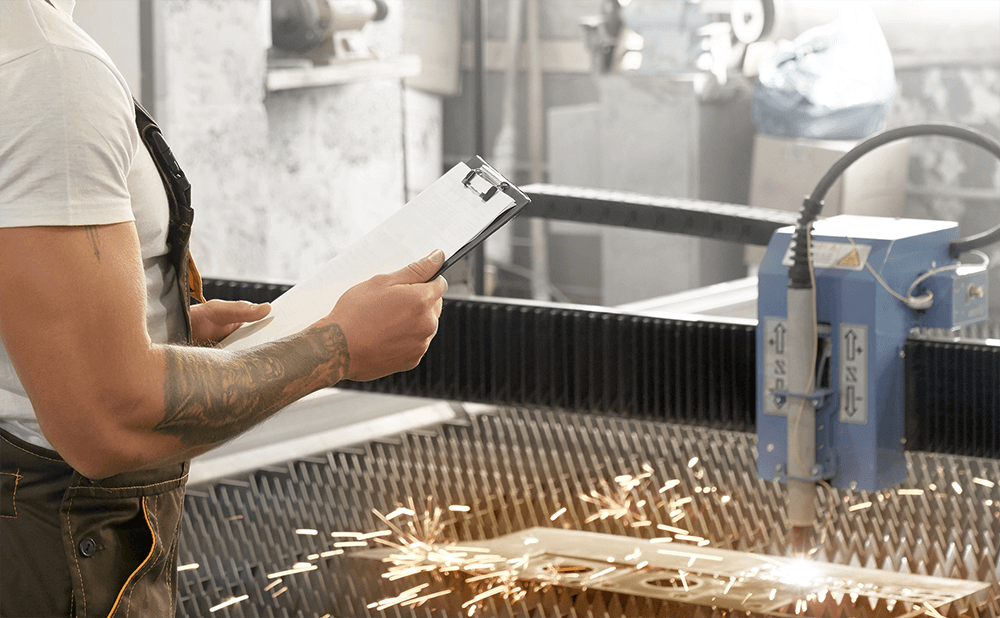

The displacement welding machine is a specialized auxiliary device designed to precisely position workpieces during welding operations. It consists of a workbench, tilting and rotating mechanisms, a feeding system, frame, and an electric control unit. It is ideal for rotary welding tasks, providing optimal positioning and welding speed. The machine can operate independently or as part of an automated welding center with manipulators and welding equipment. The rotary table features a frequency converter for smooth, stepless speed adjustment with high accuracy. Control can be achieved via a remote control panel or by integrating the system with robotic and welding controls. Through lifting, tilting, and rotation functions, the workpiece can be aligned to achieve the desired welding angle and optimal working position.